What are Wheel Stops?

What Are the Different Types of Wheel Stops?

- Concrete Wheel Stops: Durable and heavy, ideal for permanent installations in high-traffic areas.

- Rubber Wheel Stops: Flexible and resistant to weathering, often used in areas where they may need to be moved or adjusted.

- Plastic Wheel Stops: Lightweight and easy to install, suitable for temporary or light-duty applications.

- Metal Wheel Stops: Strong and durable, often used in industrial settings or where extra strength is required.

Concrete Wheel Stops

Advantages of Concrete Wheel Stops

- Durability: Concrete wheel stops are incredibly durable and can withstand extensive wear and tear.

- Stability: Due to their weight, they provide excellent stability and stay in place once installed.

- Low Maintenance: They require minimal maintenance once placed.

- Weather Resistance: Concrete is resistant to weather variations, including extreme temperatures and precipitation.

Disadvantages of Concrete Wheel Stops

- Weight:Concrete wheel stops are heavy, making them difficult to transport and install.

- Vehicle Damage: Their hard material can cause significant damage to vehicles upon impact.

- Cracking: They can crack or break under extreme pressure or after impacts, requiring replacement.

- Aesthetic Deterioration: Over time, concrete can stain and become visually unappealing.

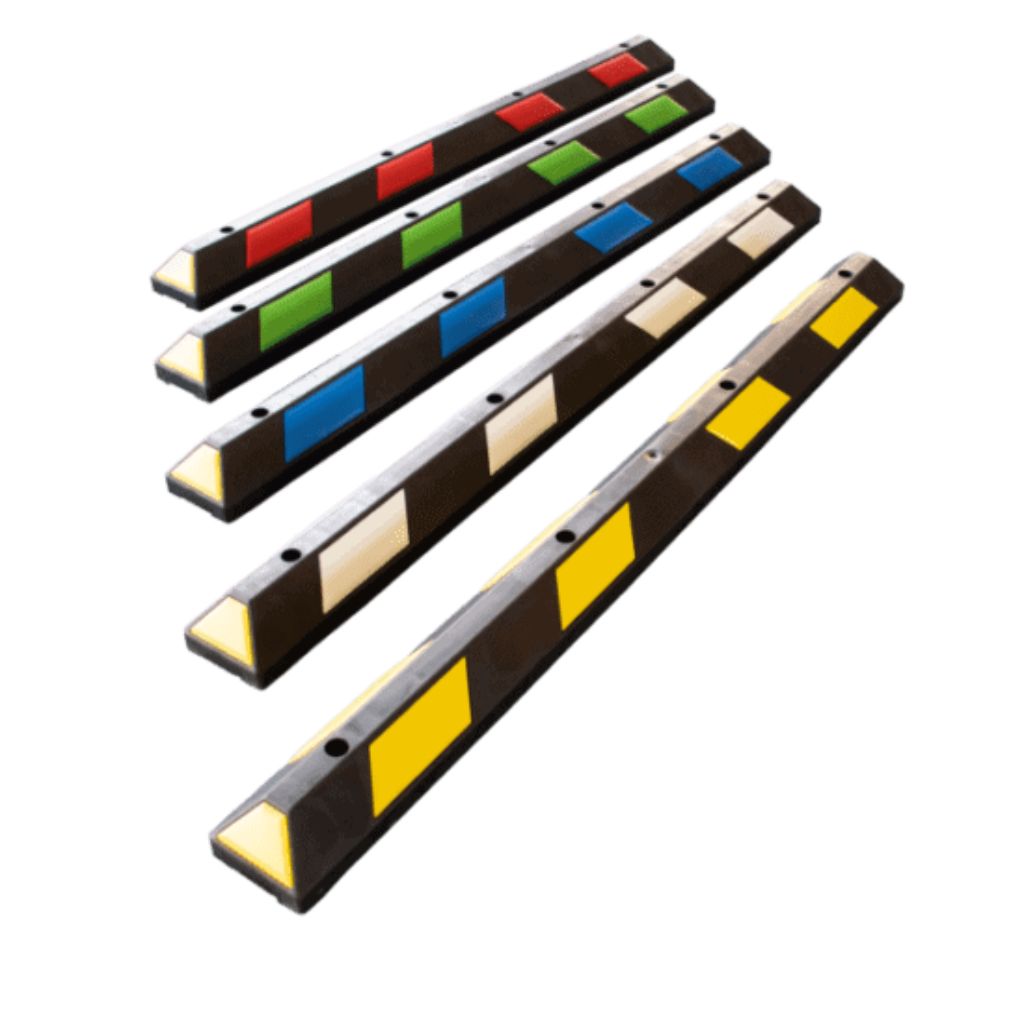

Rubber Wheel Stops

Advantages of Rubber Wheel Stops

- Flexibility: Rubber is less likely to cause damage to vehicles on impact due to its flexibility.

- Ease of Installation: Lighter than concrete, rubber wheel stops are easier to handle and install.

- Environmental Friendliness: Often made from recycled materials, making them a greener choice.

- Durability in Various Climates: Rubber remains effective under a wide range of environmental conditions without cracking.

Disadvantages of Rubber Wheel Stops

- Less Stability: They can shift more easily if not secured properly.

- Wear and Tear: Rubber may degrade over time, especially in extreme weather conditions.

- Aesthetic Changes: Rubber can fade, become discolored, or wear down visually more quickly than concrete.

- Lower Load Capacity:They may not be suitable for heavy-duty applications compared to concrete stops.

Cost Comparison: Concrete vs. Rubber Wheel Stops

- Concrete wheel stops are generally more affordable upfront compared to rubber options. However, due to their weight and the complexity of installation, the total cost including transport and installation can be higher.

- Rubber wheel stops, while potentially more expensive per unit, often incur lower installation costs because they are lighter and easier to handle, potentially balancing out the initial higher price over time.

Environmental Impact

The environmental impact of wheel stops varies significantly between concrete and rubber materials. Concrete wheel stops, while durable, are resource-intensive to produce and are not biodegradable, contributing to environmental load.

On the other hand, rubber wheel stops are often made from recycled tires, significantly reducing waste and resource use. The production process for rubber stops generally has a smaller carbon footprint and supports waste recycling initiatives, making them a more eco-friendly option.

Customization and Maintenance of Color in Concrete vs. Rubber Wheel Stops

Customization and maintenance of color are important factors in wheel stops’ aesthetic and functional longevity. Concrete wheel stops can be painted to match specific color schemes, but they require regular maintenance to keep up appearances as they are prone to fading and staining.

Rubber wheel stops are typically manufactured in various colors, with the color mixed into the material, minimizing visible wear and fading over time. This inherent color stability makes rubber stops more appealing for applications where maintaining a clean, professional look is important without frequent upkeep.