Understanding Asphalt Sealcoating

Pros and Cons of Asphalt Sealcoating

Pros:

- Sealcoating gives your driveway a fresh, black appearance, enhancing its look.

- It protects asphalt from UV rays, water penetration, and harsh chemicals.

- Sealcoating extends asphalt lifespan, reducing the need for repairs.

- It is more affordable than repairing or replacing damaged asphalt.

- Sealcoating smooths the surface and enhances traction, reducing slip risks.

- Requires an initial investment for materials and labor.

- Needs periodic reapplication, adding to maintenance costs.

- Must be applied in optimal weather, limiting timing.

- Surface requires curing time, causing temporary inconvenience.

- Improper application or low-quality products can result in discoloration.

Asphalt Sealcoating Application Techniques

Equipment and Tools Required for Sealcoating

- Sealcoating Machine: This includes both manual and commercial-grade machines designed for large areas like parking lots.

- Sealcoat Material: The type and quality of the sealcoating material are crucial for durability and appearance.

- Asphalt Sealcoat Sprayer: For an even coat and efficient application.

- Squeegees and Brushes: Used for smaller areas and to spread the sealcoat evenly.

- Blowers and Sweepers: To clear the asphalt surface of debris before application.

- Crack Filling Equipment: Necessary for repairing cracks before applying the sealcoat.

- Protective Gear: Includes gloves, goggles, and masks to ensure safety during the application process.

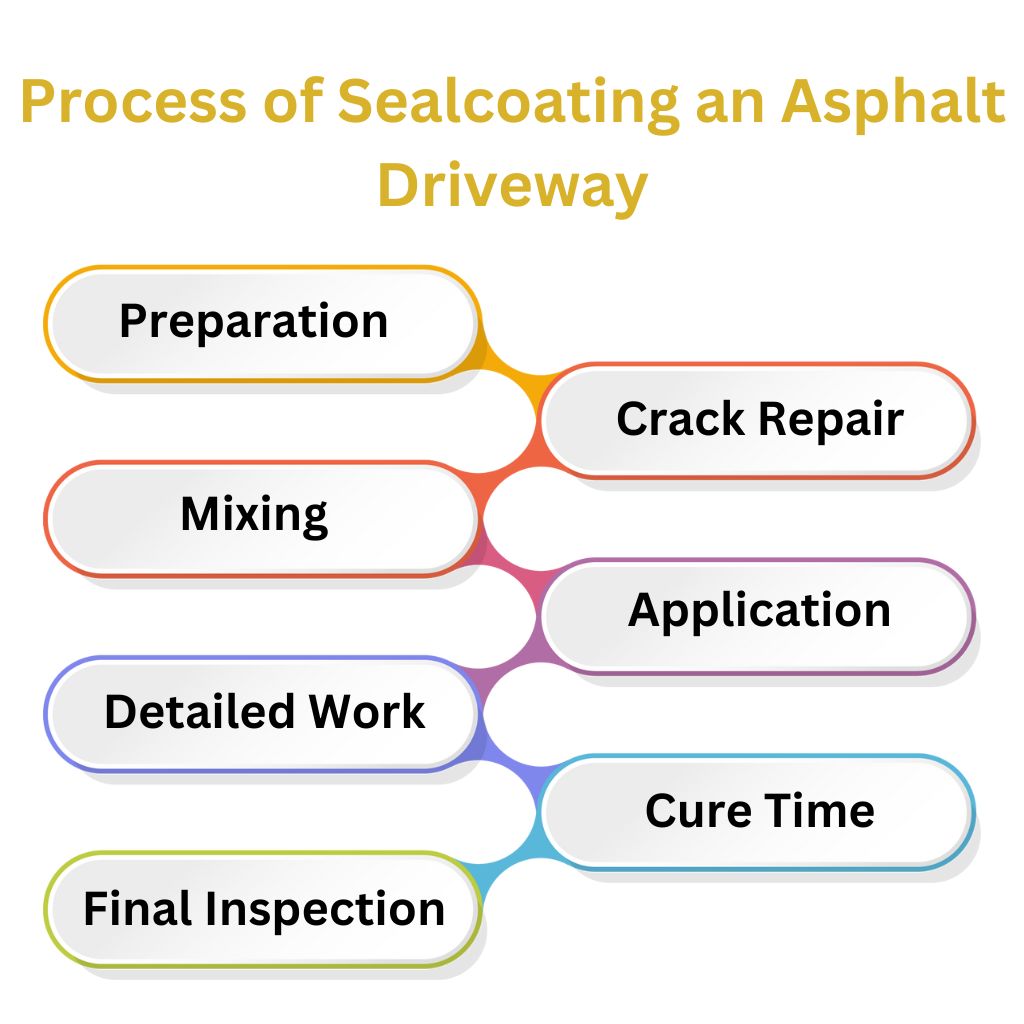

How to Properly Sealcoat an Asphalt Driveway? - Step-by-Step Application Process

- Preparation: Start by cleaning the driveway thoroughly. Use a blower or sweeper to remove all debris, dirt, and loose asphalt. This step is crucial to ensure proper adhesion of the sealcoat material.

- Crack Repair: Fill any cracks or holes with appropriate crack filling material. This prevents water from seeping through and causing further damage.

- Mixing Sealcoat: Prepare the asphalt sealcoating material according to the manufacturer’s instructions. Ensure it is mixed well for an even consistency.

- Application:Using a sealcoating machine or sprayer, apply the sealcoat evenly across the driveway. For asphalt sealcoating driveway surfaces, make sure to overlap each pass slightly to avoid streaks and ensure full coverage.

- Detail Work: Use brushes or squeegees to apply sealcoat in hard-to-reach areas and edges. This ensures that the entire surface is sealed.

- Cure Time: Allow the sealcoat to dry completely. How long does sealcoating take to dry depends on weather conditions, but generally, sealcoat dry time can range from 24 to 48 hours. Ensure the surface is kept clear of traffic and debris during this time.

- Final Inspection: After the sealcoat has dried, inspect the surface for any missed spots or areas that need touch-up.

The Impact of Timing and Weather on Asphalt Sealcoating

Asphalt sealcoating is highly dependent on weather conditions and timing to ensure a durable and effective seal. Sealcoating should ideally be applied in warm, dry weather with temperatures above 50°F and low humidity levels to speed up drying. The best seasons for sealcoating asphalt are late spring, summer, and early fall. Rain within 24 hours of application can wash away the sealcoat, leading to uneven coverage and potential damage, so it’s important to check the weather forecast.

Wind can blow debris onto the freshly applied sealcoat, which can cause imperfections in the finish. The sealcoat dry time is typically 24 to 48 hours, but full curing might take up to 72 hours in ideal conditions. Considering these factors can ensure a successful sealcoating application that provides maximum protection and longevity to your asphalt surfaces.

How Long Does it Take to Sealcoat a Driveway?

What are the Common Driveway Sealing Mistakes to Avoid?

- Insufficient Preparation: Failing to properly clean and prepare the surface before applying the sealcoat can result in poor adhesion. Always remove all debris and repair cracks prior to sealing.

- Incorrect Weather Conditions: Applying a sealcoat in unsuitable weather is a major mistake. Ensure the temperature is above 50°F and no rain is forecasted for at least 24 hours.

- Overapplication: Applying too much sealcoat can cause it to crack and peel. Use a consistent and even layer to ensure durability.

- Underapplication: Conversely, applying too little sealcoat won’t provide adequate protection. Follow the manufacturer’s guidelines for the correct amount of sealcoat material.

- Inadequate Drying Time: Not allowing enough time for the sealcoat to dry can lead to tracking and uneven coverage. Ensure the surface is given sufficient time to cure completely.

- Using Low-Quality Materials: Investing in high-quality asphalt sealcoating products ensures better results and longevity. Cheap materials can lead to discoloration and uneven wear.

- Ignoring Edge Work: Neglecting the edges and hard-to-reach areas can leave parts of the driveway vulnerable to damage. Use brushes or squeegees for detailed work to ensure full coverage.

- Lack of Maintenance: Sealcoating is not a one-time solution. Regular maintenance, including reapplying the sealcoat every 2-3 years, is necessary to maintain the protection and appearance of the asphalt.